Leaside residents who frequent the Loblaws store on Redway Rd. or enjoy hikes in Crothers Woods may be surprised to learn they are near the site of Plywood Fabricators, a company that played a significant role in supplying landing craft for the war effort in World War II.

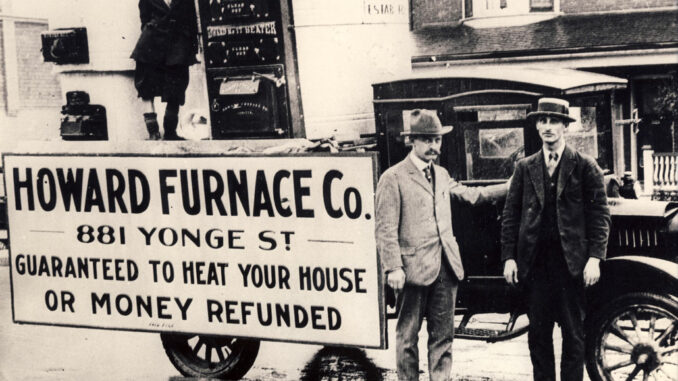

The company was an offshoot of the Howard Furnace Company, which was acquired by Toronto businessman Robert Hughes in 1915. Robert is the great-grandfather of local home technician Rob Hughes, who was featured in our May 2022 issue. Robert’s sons, King (Rob’s grandfather) and George, took over the business in the 1930s. During the war years, the company also manufactured furnaces for the Department of Defence, providing heating systems for barracks and hangars across Canada.

On one of King’s regular visits to Ottawa to discuss heating systems with the Department of Defence, he learned that the government was looking for a company to build landing craft called Ramped Cargo Lighters (RCLs), which could be assembled on ship or land. The brothers and their friend and consultant on naval matters, Ted Shipley, worked out a manufacturing process, and after, making a presentation, were granted the contract and asked to complete the first order for 200 craft as soon as possible.

King then set up a separate company for manufacturing the RCLs called Plywood Fabricators. (The furnace company continued with its production at the same time.)

He purchased property in Leaside near where the Loblaws sits today, as it had to be close to a railway line for easy transport.

Because the order was required immediately, Rob explains that the construction of the RCLs started in the parking lot close to the rail spur line even before the plant was completed. In fact, the factory was built over the spur line so craft could be loaded in all weather conditions.

The lighters were built in sections of plywood over wooden frames to simplify shipping, then were transported to the east coast, and shipped to war zones where they were assembled in the theatre of operations. The craft were described as “shallow-draft, barge-like boats,” 52 feet long and 18 feet wide, and equipped with two 100 bhp Gray Marine six-cylinder engines. The craft, which had a crew of four, could be used to carry troops, two light tanks, one heavy one, or four Bren Gun Carriers.

According to Rob, King Hughes was a pragmatic businessman who saw the work as “a challenge to be addressed, rolled up his sleeves and took it on.” Apparently, a recruiting officer told him that he was needed where he was, in his manufacturing role, to support the war effort.

The last contract was filled in 1944. By the end of that year, Plywood Fabricators had built 345 of the landing craft.

When the war ended, Plywood Fabricators started building houses in sections with their surplus materials. These homes were assembled on site, some of the first “prefabricated” houses built for returning war veterans and shipped to areas in Toronto, such as Pharmacy and St. Clair, Oakville and Hamilton.

King eventually refocused his efforts on the heating and cooling business, Plywood Fabricators was wound down, and the building in Leaside was sold to a glass manufacturer. The company had been very successful in serving Canada and its war effort.